We use cookies to personalise and enhance your experience.

Google is often the first place customers go to when they’re looking to purchase a product or when they want up-to-date information about any product. They’ll want to find out:

- if their preferred products are available locally,

- which local stores offer the best rates for these products,

- and if the products are in stock at their local stores.

Google's my business profile lets businesses offer exactly this by fetching information about the products directly from their inventory. Shoppers can see specific items and find out if they’re in stock at nearby stores.

Google’s live inventory feature gives out all the information — from the availability of the products and best rates to local options that are best suited for the customers. The products will appear across all Google pages — Search, Images, Shopping, Maps, and Lens.

Setting up, tracking, and managing the inventory hence becomes extremely crucial for online businesses. Especially, when you want to reach the local customer base. It is hence important that your Google business profile stays constantly refreshed. Otherwise, you will bleed customers.

Small businesses need to undergo the implementation of a lot of processes including building a social media presence, adopting SEO best practices, streamlining their processes, managing the supply chain, etc. However, inventory management remains the most crucial aspect of all. This article shares some top suggestions for perfecting the inventory management processes, at a time when it is more important to do so than ever.

Inventory Management: A Brief Introduction

Being a crucial aspect of supply chain management, inventory management ensures that your business always has the right products in the right quantity for sale at the right time.

For example, if you’re purchasing products that sit on your warehouse shelves for long – it means that you’re not benefiting from your investment. On the other hand, not having adequate inventory to meet the demand can result in lost sales. A streamlined inventory management process can prevent this from happening.

Why Is Inventory Management for Small Businesses So Important?

Businesses of all sizes need an inventory tracking mechanism to manage costs and ensure they have an ample supply of products to meet customer demand. Effective inventory management allows businesses to

- reduce costs and maximize sales

- avoid products being out of stock

- enable real-time tracking of stocks

- avoid funds getting tied up in excess stocks

- and ensure that their products are sold in time to avoid spoilage

9 Tips for Small Business Inventory Management

1. Categorize Your Inventory Using the ABC Analysis

All products are not created equally and do not cater to all customers. ABC analysis is a way of organizing inventory based on the 80/20 rule i.e. 80% of revenue comes from 20% of your products. This works wonders for maximizing the overall turnover time.

The ABC inventory management puts your products into three categories based on their ROI and value to your business. Here’s how you can classify your inventory:

A: Items that are of high value and are small in number

B: Items that are of moderate value and are moderate in number

C: Items that are of small value and are large in number

Applied to inventory:

Here’s an example of ABC analysis applied to all the products based on their annual consumption value.

Classification | Percentage of inventory | Annual consumption value |

A | 10-20% | 70-80% |

B | 30% | 15-25% |

C | 50% | 5% |

2. Accurately Analyze Your Inventory

One of the first steps of managing your inventory better is knowing what you have in stock. Your order fulfillment technology should enable you to accurately track your stock levels, identify shortages, mitigate overstocks, and provide real-time information.

Here are five inventory management KPIs for performance analysis:

Know Your Inventory

If you do not know your inventory in and out, you’ll not be able to make decisions when a problem arises.

For instance, if a specific product languishes on your warehouse shelves for long, it is a signal that the demand for the product has declined. You’ll need additional promotional efforts to boost awareness and demand for that particular product.

You’ll need to have a system in place that gives you access to all the key bits of information. This way you can start drawing comparisons and making informed reports on a monthly to yearly basis. Start with asking yourself the following questions. If you’re having trouble finding answers, it might be time to get your ducks in a row:

- How much of a particular product do you have in stock?

- How much of that product is reserved for customers?

- How much of it has been sold in the last X months?

- How much of it do you need to order?

- What’s your best seller?

Track Low Stock Levels

Excess stocks waste both — space and capital. If you have items that haven’t sold at all in the past year, it is probably time to stop stocking those items. You can consider various strategies for getting rid of that stock — like by providing a special discount or promotion.

By identifying slow-moving stocks early, businesses give themselves the best chance of selling them before the product becomes completely obsolete. Some tactics to deal with slow-moving stocks include:

- running a special promotion,

- transferring the stock to another location where it sells faster,

- or selling the stock to a third party.

Keep in mind that:

Some items may have a higher sales velocity during different times of the year. For example,

- Halloween costumes in October,

- Bathing suits in spring/summer.

Therefore, be discerning about what you do and don’t restock.

Inventory Shrinkage

Inventory reduction is one of the easiest ways for small businesses to save money. You can use analytics to determine how much of a product you will need at any given time based on previous sales data. Then you can shrink the amount of inventory and limit it only to a number of products most likely to sell.

3. Accurately Forecast Demand

With demand volatility at an all-time high, it is difficult to define universal standards of demand while planning your inventory. Accurate demand forecasting is easier said than done. The ability to accurately forecast demand plays a significant role in managing inventory costs and maximizing sales opportunities.

A lot of factors contribute to getting an accurate forecast for future growth. Keep these factors in mind while forecasting your business’s demand:

- Extensive product ranges

- Multiple sales channels

- Promotional offerings

- Price changes

- Your business’s sales history

- Seasonality

- Current market trends

How to Forecast Demand Accurately

Demand forecast is one of the important blockchain applications for inventory management. Blockchain enables warehouses, manufacturers, suppliers, and distribution centers to connect with each other. It keeps a permanent record of every transaction that takes place.

Speaking of transactions, Shopify has started accepting Bitcoin and other cryptocurrencies as a mode of payment method and that says a lot about rise of blockchain in not only demand forecast but also fintech space.

Warehouse inventory management can forecast demand accurately and hence always have the right type and quantity of stock needed to meet expected demand.

4. Streamline Your Workflows: Analyze and Prioritize

Do you have set guidelines for different workflows in your business?

If not, now is the time to streamline your processes.

You do not want your orders to get stuck in the process due to a lack of streamlined workflow.

For example, if you do not have a streamlined process for inventory management during your busiest seasons, you may lose customers due to longer turn-around time.

Streamlining will eventually help you prioritize workloads, save time, encourage good practices, and increase efficiency. Therefore having a streamlined approach for all your channels of distribution is a must for small businesses.

It includes:

- Nailing down a standardized plan to address issues when they occur.

- Having a plan for different scenarios that your business is likely to encounter.

- Having a set resolution to resolve these scenarios.

- Having a set method to prioritize workloads and manage them before the ETA.

How to Prioritize Your Workflows

If you’re unsure of where to begin, start by using the prioritization framework of the Eisenhower Matrix. Divide your work into four quadrants based on its urgency and importance and take action accordingly.

5. Adopt the FIFO Approach

What comes in first, must go out first.

Products should sell in the same chronological order as they’re purchased or created. The FIFO (first-in, first-out) approach of inventory management seeks to sell older products first. This makes the business less likely to lose money when the products expire or become obsolete.

It includes selling the oldest inventory items first and maintaining the newest items in the inventory. The FIFO approach is especially beneficial for perishable items — like plants, food, cosmetics, organic items, etc. You don’t want your goods sitting around your shelves for too long and getting damaged, or out of date (and unsellable.)

The best way to apply FIFO in your warehouse is to add new items from the back so the older products are at the front.

6. Create Standardized Processes

Formalizing, standardizing, and regularly reviewing processes can minimize human error and ensure that the processes work efficiently.

For instance, being consistent in how you receive your stocks can help you minimize errors and control costs. A standard process to receive, verify, unpack, and count products and a similar process for picking, packaging, and shipping products — can minimize variation, reduce obsolescence, and add revenue to your bottom line. Here are some tips to standardize your processes.

- Leverage data and information for making decisions.

- Automate redundant tasks like counting stocks.

- Define processes and sub-processes in detail.

- Ensure everyone on your team is aware of the set workflows.

7. Warehouse Management

The organization of the stockroom has a significant impact on the efficiency of your supply chain. It becomes even more important for special requirements for perishable or fragile stock.

Managing your space well means you can store more inventory and take full advantage of your warehouse. This helps businesses control costs and boost sales. Make sure you do it right!

Use a Barcode System

Barcodes aid with inventory management.

Its encoded information makes it faster and more accurate for businesses to manage their inventory. Barcodes allow the tracking of both incoming and outgoing inventory easily. The barcode identifies information such as size, color, location, production date, expiration date, and so on.

For instance, a certain product that will expire first should be sold first before it becomes obsolete. With the help of a barcode, you can quickly identify which product to send first.

Barcodes can also be used to conduct a quick inventory count. It can live with the products throughout their life cycle — from when they’re manufactured to even after they’re sold. This eventually imparts more visibility to the inventory and helps businesses run more efficiently.

Organize Stockroom

When it comes to organizing your stockrooms, you need to be strict. It’ll help your business to operate in a more streamlined manner. A disorganized and chaotic warehouse can lead to lost inventory, resulting in less revenue and customers.

Here are some important tips to consider while managing your stockrooms:

- Physically differentiate and categorize your stocks

- Put your best sellers in clear sight

- Make use of vertical spaces

- Set up a label and barcode system

- Invest in robust storage units

- Create an area for orders being shipped and received

8. Embrace Inventory Management Technology

For small businesses, managing the first ten things on the list manually using spreadsheets and notebooks is doable. But as your business grows, manual processes will only restrict your growth.

You’ll find yourself spending more time on inventory than you do on your business. You may also risk your stocks getting out of control. This is where leveraging efficient inventory management technology comes into the picture. While investing in technology, prioritize integrated systems that work together — like POS technology.

Point-of-sale (POS) Technology

A POS technology can help your small business track inventory and stock in real-time. When items sell, the software would automatically update the inventory levels.

Plus, when your POS software integrates seamlessly with your inventory management system, it’ll help you track ongoing and outgoing inventory easily. This reduces the data entry errors from your inventory counting and you’ll have better reporting capabilities.

For example, you can create dashboards that provide information such as profit margins for specific items and inventory turnover.

9. Build Tangible Relationship With Your Suppliers

The kind of suppliers you partner with imparts a huge difference between disaster, and disaster averted. This is why it is important to build tangible relationships with multiple suppliers. Monitor your suppliers’ performance regularly to see if you’re getting your money’s worth.

The Bottomline

Every business has its own way of keeping things running smoothly. However, the importance of control remains the same. An errorless inventory management system will keep things running smoothly and ensure that everything runs under control. We hope that the above tips help you leverage the full potential of inventory management.

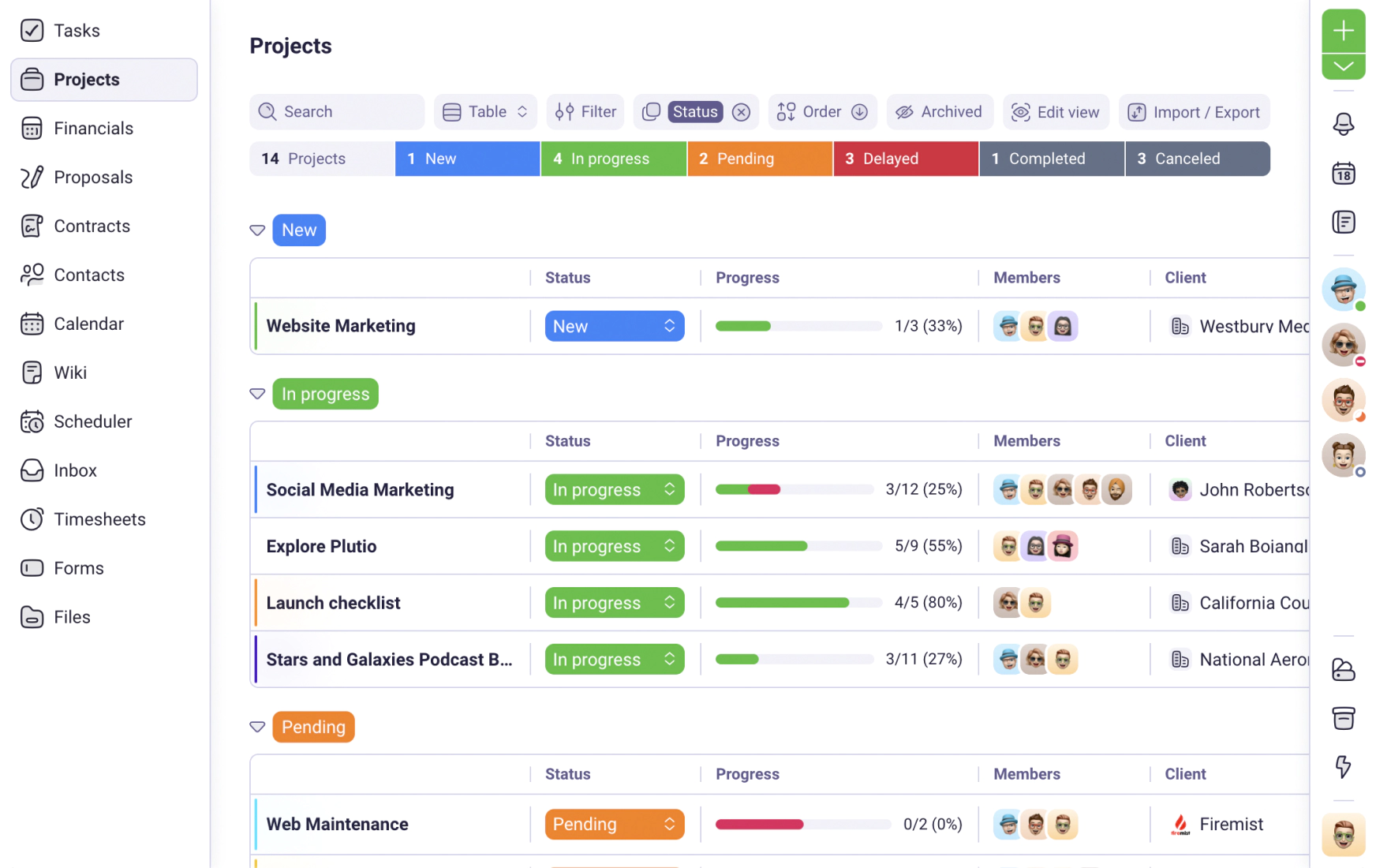

Have you tried Plutio yet?

The only app you need to run your business and get work done.

Try Plutio for FREESupercharge your business

The complete toolkit to run your business

The intuitive all-in-one solution to manage and collaborate on projects, share files, build forms, create proposals, get paid, and automate your workflow.

No credit card required